Extrusion Tap

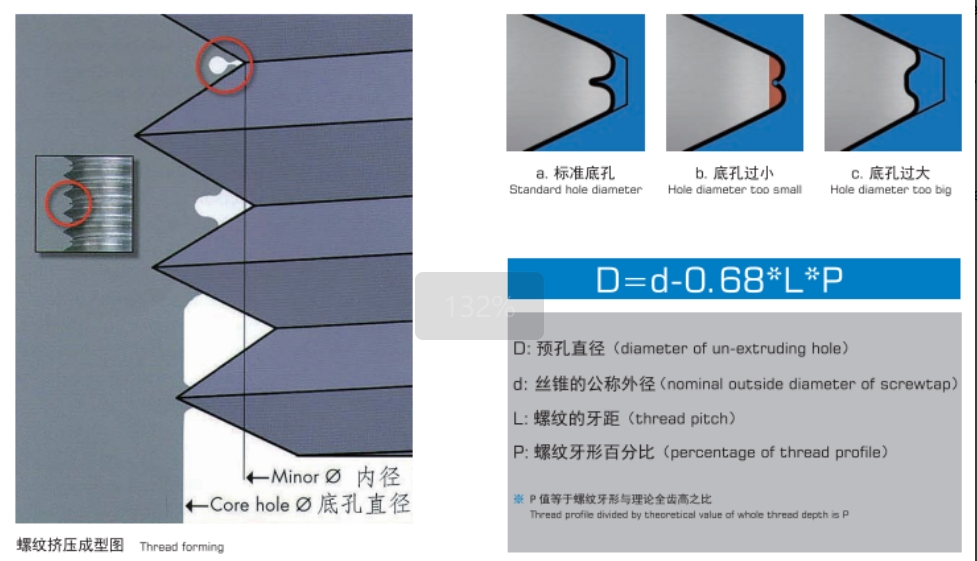

Extrusion tap is a new type of thread tool that uses the principle of metal plastic deformation to process internal thread. It has no cutting edge and chip groove, but has one or more lubricating oil grooves. The tap has a diamond shape and is a chipless processing technology. The thread extruded by the extrusion tap has a high surface finish, the metal fiber of the thread will not break, and a cold hard layer is formed on the surface, which can improve the strength and wear resistance of the thread. It fundamentally solves the chip removal problem from tapping. Because there is no scrap, it is more conducive to the assembly of the thread. When tapping, there is no need to cut metal, but to form threads through metal plastic flow, so its diameter is larger than the thread minor diameter, and the extruded thread tooth shape is U-shaped. The normal tooth shape accounts for about 65%~75% of the full tooth height. If the pre-extrustion diameter before tapping is too small, the tapping torque will be increased, making the tap easy to wear and break. On the contrary, if the pre-hole diameter before tapping is too large, the tapped thread minor diameter will be too large. Therefore, to obtain qualified threads, the pre-extrustion hole size before tapping must be controlled quite accurately. The theoretical value of the pre-extrustion diameter can be calculated according to the following formula.