Brand Introduction

Located in Dongguan, Fourocean is the leading in-die automation machine manufactuer in China. We have been dedicated in engineering and production of quality in-die tapping unit, in-die insertion unit, in-die chamfer unit, in-die inspection unit etc for over 20 years, with mature and robust technology widely praised by China and global clients like Magna, Adient, Bosch,BYD, Misumi, Apple,Haier etc. Our tailor-made tapping/insertion solutions are designed to satisfy the production environment and constraints of our clients, the operations of tapping (from M0.6 to M45, single to multi tapped holes, in all directions) and insertion (bushing, spindle, ball joint, rivet, stud, pin…) could be achieved in the stamping tool during forming/drawing process,so as to eliminating the secondary tapping/insertion. Till now,our team has achived more than 100 technical inventions, utility and appearance patents with independent intellectual property rights. We will continue to improve the technical process and standards of in-die tapping, and actively participate in the innovation and transformation of the automotive parts field, providing perfect solutions for the hole-flanging, deep drawing, cold forging&thickening of 420~990 high-strength parts.

Application Industry

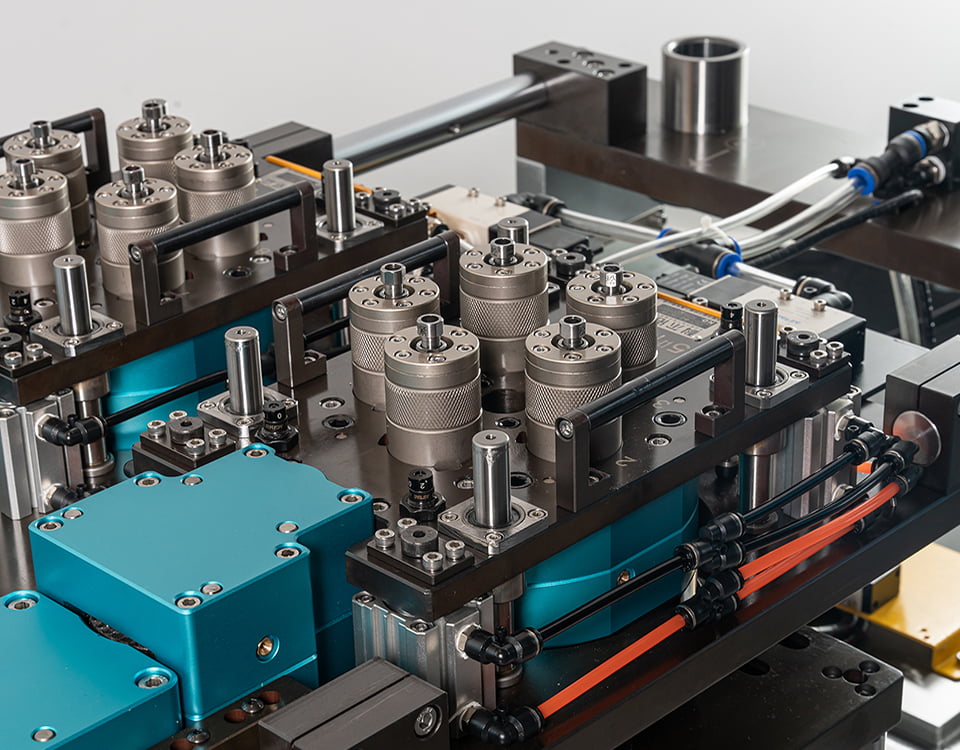

Fourocean In-die Tapping

IN-DIE TAPPING has become very mature and competitive alternative to secondary off-line tapping to save larbor cost and improve production efficienct. The following are some of the features of the In-die tapping machine:

– Simple design and easy installation;

– Vertical, horizontal and oblique tapping direction;

– Single & multiple-hole tapping in a single station;

– Tapping size ranging from ØM0.6 to M45;

– Min hole center distance: 10 mm;

– Hole center distance is adjustable;

– Mechanical & servo tapping workstation which could be used in-line and off-line;

– Fast replacement for screwtap within 1 minute in press;

– Threading could be left or right;

– Various installation method to suit different requirements or restrains from clients ways, such as fixed, floating, suspended and arch bridge.

Technical Integration and Service

Tailor-made Solution:

We will provide tailor-made solutions for customers according to different part feature,press condition, tool type and condition etc to ensure safety, stability,cost-saving and high efficiency. For example, our tapping machine direction could be downward, upward, horizontal and inclined, and it can be installed in different ways, such as fixed, floating, suspended and arch bridge. During discussion stage, we will carefully check your product and tool structure to ensure the perfect integration of stamping tool and tapping machine.

Quality Production:

Whether core parts(like gear, bearing), auxiliary electronic components, or maching housing, we always pursue quality first. We use larger hardened gears and shafts plus roller and ball bearings throughout the gear train, we use solid steel to construct all housing with latest CNC technology, so we could deliver our customers with worry-free fine machines which has strong and stable performance and working life.This is main reason why we stand out from other competitors.

Startup and Maintenance Training:

Customer just need to make the tool ready, we will make proper installation and layout of complete tapping/insertion system according to on-site environment. During startup days, we will also explain in detail the working princeple of tapping/insertion machine,and train your team in detail how to use,debugging and make regular maintenance. We will also provide paper or electronic documents of installation, wire connection and maintenance. With our documents and videos, some customers even can make succeful installation by theirself.